Pneumatic Liquid Oxygen Fill/Abort Valve

In 2024, the rocket team switched from a nitrous oxide/paraffin wax hybrid to a liquid oxygen/paraffin wax hybrid rocket. The jump to using cryogenic oxidizer was huge, from dealing with cryogenic temps to maintaining oxygen safety, it was a large challenge that required a complete redesign of our fluids system. We had to design and manufacture three cryogenic liquid oxygen valves and redesign our gaseous nitrogen pressurant system. In my freshman year, I was tasked with designing our new pneumatic liquid oxygen abort/fill valve.

We launched our hybrid rocket at the FAR-OUT rocketry competition in the summer of 2025. FAR-OUT rules dictate we must have an abort valve that can drain the LOX tank within 30 minutes. Alongside this, the valve has to be passively open and closed when pressurized by GN2. We also had to run this abort/fill valve parallel to the LOX run valve, giving us a max diameter of about 1.54 inches between the run valve and the wall of the airframe to fit this valve. I designed the valve to operate with a minimum pilot pressure of 250psi. On the vehicle, we used a pilot pressure of 700psi.

Given these three constraints guiding my design, here is what I came up with!

The piston inside is held in an open position with a spring. Once the GN2 is pressurized (700psi), GN2 will push up on the bottom of the piston with about 283 lbf, closing the valve, then the LOX tank will be filled. I worked out force balance calculations to ensure the piston would close under 250 psi, significantly below our 700psi operating pressure/MEOP. Additionally, I ran FEA in Fusion on all components to ensure the valve could withstand the pressure forces it would experience.

Operation:

In an abort scenario, we’ll open the abort solenoid valve on the GSE panel. In the case of a failure of the abort solenoid, we have a ball valve attached to a long rope so we can perform a manual abort. Either abort method will lead to the depressurization of our onboard pilot GN2 line (no nitrogen gas pushing up on the piston), then the piston is pushed down both by the force of the LOX and spring. The expected drain time of the 22L LOX tank is around 30 seconds.

Sealing and materials selection:

Due to LOX compatibility requirements, aluminum was not an option for materials selection. Instead, everything was machined with 303 stainless steel. Cryogenic temperatures prohibit us from using regular O-rings, so we elected to use PTFE spring-assisted seals for the sealing between the two bodies of the valve. We also machined a PTFE insert for the seal between the piston and tank endcap. Due to the space constraint, instead of creating flanges to put the two halves of our valve together, I opted to add six holes for 8-32 bolts that run through the walls of the valve.

Machining:

The abort valve was machined in-house in late February on a Haas ST-20Y and Haas Mini Mill. I learned how to do CAM in Fusion and machined the components with my team leads. Stainless steel is a poor heat conductor and has a tendency to work-harden, making it more difficult to machine compared to a material like aluminum. Alongside this, the tolerances for this part are small and incredibly important due to the sealing requirements. For example, we needed a .006-inch diametric tolerance for our spring-assisted seals. To account for tolerance stackups and concentricity offsets in the valve, I also had to ensure the piston would seal with the PTFE seat on a very sharp knife edge. We expected machining stainless steel to be difficult, and the consequences of a crash were much more significant compared to machining a material like aluminum. However, it went by fairly seamlessly with minimal problems.

Valve diameter: 1.454 in

Valve height: 1.419 in

LOX inlet: .05 in^2

LOX outlet: .05 in^2

We ran a hydrostatic test to 1.5 times MEOP, and the valve passed:

Once the motor was fully integrated, we ran a successful abort test. The valve also performed as intended at cold flows, static fires, and our launch at FAR-OUT in summer 2025!

Fill/Abort Valve integrated and connected to LOX umbilical

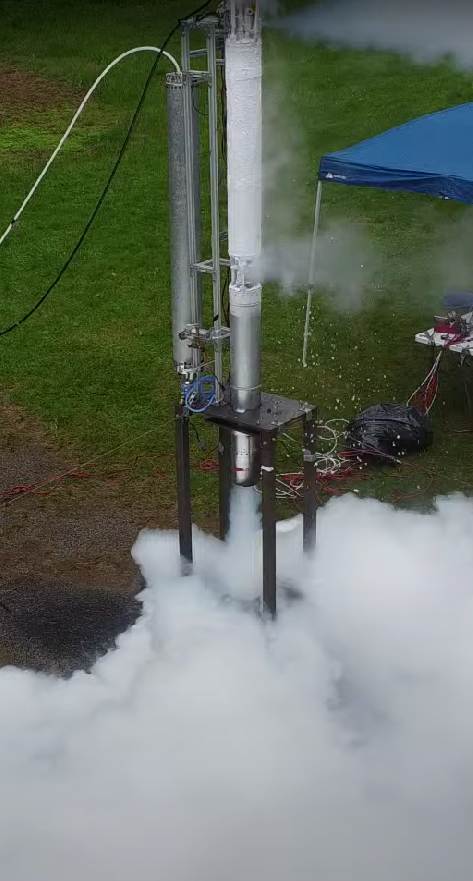

Cold Flow

Static Fire!